For decades, quantum theory was a realm of abstract science, a field reserved for physicists exploring possibilities that seemed far removed from the realm of manufacturing. Today, that gap is beginning to narrow. Quantum effects, once considered obstacles to control, are now being studied as tools for advancing semiconductor processes. Erik Hosler, a veteran in semiconductor material and process research, recognizes how this shift is changing the way experts view innovation in fabrication. His observation reflects a growing belief that the principles shaping atomic behavior could someday influence the design and operation of production technologies.

This attention to quantum research arises from necessity as much as curiosity. Traditional methods of scaling face growing physical and economic barriers, and new concepts are needed to maintain progress. The semiconductor industry has reached a point where the smallest structural features operate on dimensions where quantum mechanics already governs behavior. Understanding that relationship is no longer optional. The transition from theory to application has begun, and the idea of merging fundamental physics with practical engineering is moving closer to reality.

Bringing Quantum Concepts to the Cleanroom

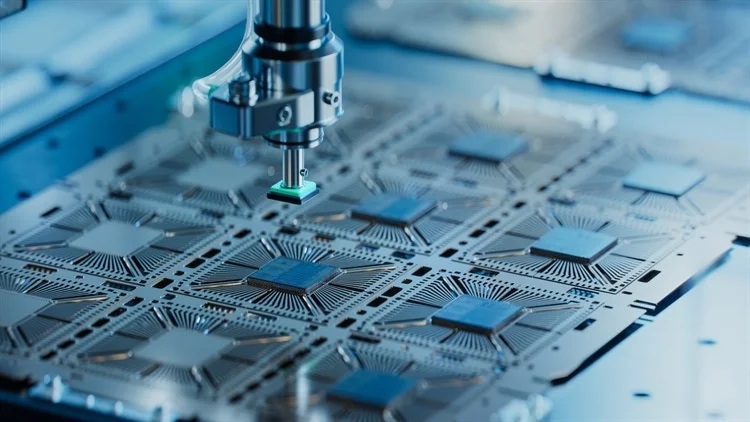

Control has always been the ultimate objective in manufacturing facilities. Every improvement in chipmaking depends on managing light, temperature, and chemistry with increasing precision. Quantum research introduces a new level of subtlety to that control. Phenomena such as electron tunneling, superposition, and entanglement are no longer confined to the laboratory. They are becoming integral to how engineers think about energy flow and material interactions at the nanoscale.

The prospect of using quantum properties to refine production remains distant, but the groundwork is already being laid. Researchers are experimenting with light sources that operate at wavelengths capable of revealing new patterns in material behavior. These studies provide insight into how atoms respond to energy at the most minute scales. The knowledge they yield could someday improve measurement accuracy or enable more selective exposure methods in chip patterning.

The Physics of Possibility

Interest in quantum approaches is growing because the limits of classical physics have become unavoidable. As process geometries continue to shrink, engineers must address behaviors that standard models cannot explain. The randomness that affects lithographic precision, for instance, has its roots in quantum probability. Instead of treating these effects as unwanted interference, researchers are exploring ways to harness them.

The conversation now centers on translating this understanding into manufacturing benefits. Quantum effects could help create new types of sensors, improve energy efficiency, or refine control over chemical reactions during fabrication. The potential remains uncertain, yet the willingness to examine the intersection of physics and production marks a cultural shift in how progress is pursued. The industry has learned that even exploratory science can yield insights that improve established processes.

A Research Landscape in Motion

Efforts to integrate quantum research into discussions about semiconductors reflect the broader development of technology conferences and consortia. What was once a specialized topic now sits alongside mainstream engineering presentations. Panel sessions that previously focused solely on optical systems or process chemistry now include discussions about how quantum theory might influence future design strategies. This openness signals that manufacturing professionals are ready to engage with ideas once considered too theoretical for the factory floor.

Erik Hosler emphasizes, “Last year, we included MEMS and MOEMS, and we will keep expanding to quantum to make this a place to ask questions … Lots of great things are going on, and something will emerge.” His comment illustrates the spirit of inclusion shaping modern research gatherings. It emphasizes that innovation often begins by asking unfamiliar questions and giving unconventional ideas space to grow.

The reference to expanding discussions toward quantum topics reflects a recognition that progress depends on curiosity as much as control. By widening the scope of conversation, the community creates an environment where unexpected collaborations can form and new directions can be discovered.

From Curiosity to Capability

Turning quantum concepts into usable manufacturing techniques may require sustained effort. The path involves developing instruments that can consistently observe and measure quantum events, translating laboratory results into industrial data. This translation from scientific principle to production strategy mirrors earlier transitions in lithography and materials science. Each stage demands persistence and interdisciplinary communication.

Several organizations are already experimenting with hybrid research environments where physicists, chemists, and engineers work together on nanoscale phenomena. These collaborations aim to identify which quantum behaviors could be applied directly to fabrication. Some focus on metrology, exploring whether quantum sensors can improve the detection of defects or enable more accurate alignment systems. Others investigate energy transfer within materials to understand how quantum coherence might affect thermal performance or device reliability.

Bridging Theory and Practice

Quantum research challenges long-held assumptions about control. Traditional manufacturing depends on repeatability, while quantum behavior is inherently probabilistic. Reconciling these two perspectives is a complex task. Yet this tension also presents an opportunity. By studying uncertainty itself, engineers may find new ways to predict and manage variability in production. This mindset treats randomness not as failure but as data.

Such thinking aligns with the broader movement toward adaptive manufacturing, where systems respond dynamically to environmental and process feedback. The same principles that describe quantum behavior could inform algorithms for real-time process correction or quality optimization. Even if direct quantum fabrication remains distant, its philosophy is already influencing how process engineers design experiments and interpret results.

Curiosity as a Manufacturing Mindset

The attention surrounding quantum ideas shows that the frontier of chipmaking is as much intellectual as it is technical. What once seemed abstract now inspires tangible exploration, and every experiment brings new questions about what can be measured or controlled. The progress made in understanding these phenomena may not immediately transform production, but it strengthens the foundation on which future methods will stand.

In this environment, innovation arises not only from tools and formulas but also from an openness to learning. Quantum thinking encourages observation without premature judgment, a valuable trait for a field facing growing complexity. As researchers continue to examine the smallest scales of energy and matter, the link between curiosity and capability becomes clearer. Progress in manufacturing has always depended on precision, and now, it also depends on imagination.